Understanding the Fundamentals of Caisson Drilling for Engineers

Delving into the Basics of Caisson Drilling

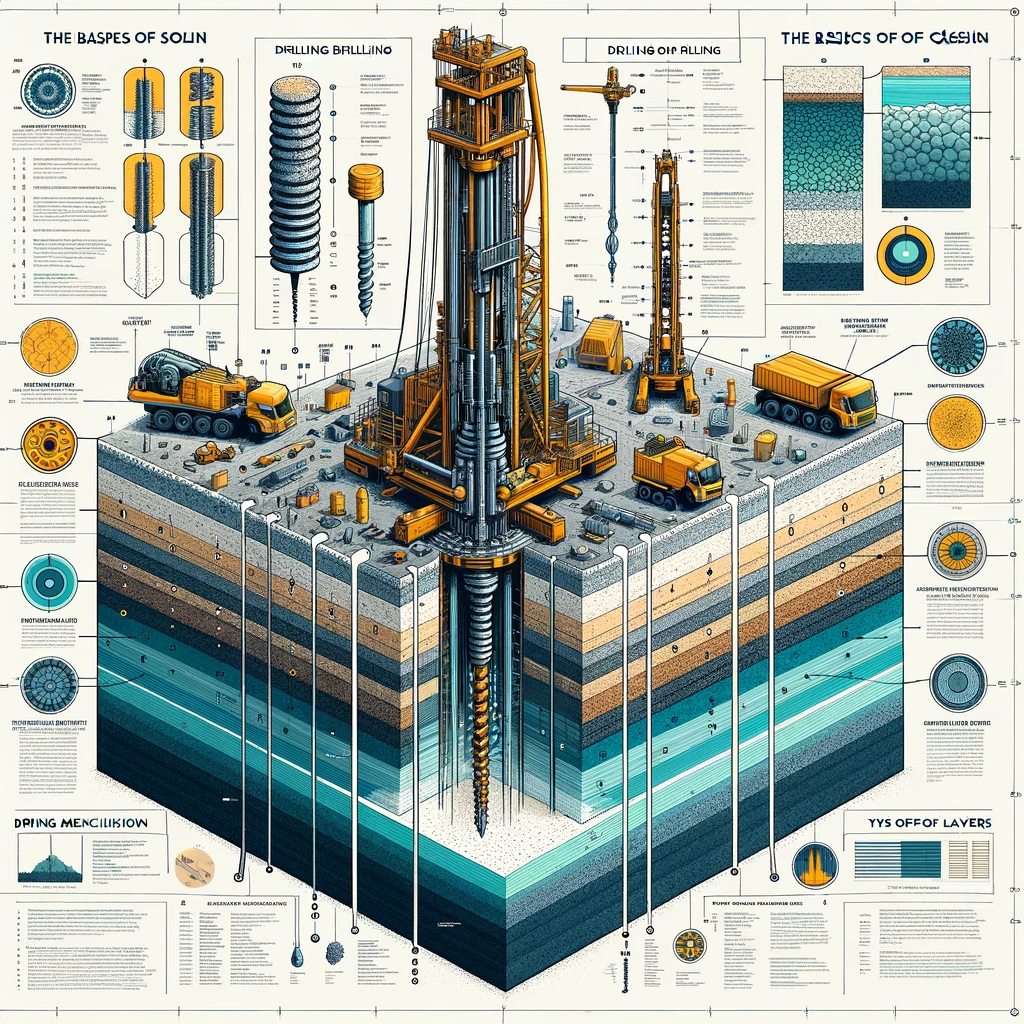

Understanding the fundamentals of caisson drilling is crucial for engineers involved in the construction of foundations at significant depths. Caissons, also known as drilled shafts or piers, are deep foundation supports that are constructed by placing fresh concrete and reinforcement within a drilled shaft. To begin the caisson drilling process, engineers must determine the size and depth of the caisson needed to support the structure. This involves researching the soil conditions, understanding the bearing stratum or bedrock, and clarifying the definitions and terminology within the caisson drilling industry. By grasping the essential tools and equipment used in caisson drilling, engineers can tackle projects with confidence and avoid any pet peeves that may arise during the excavation process.

Defining Caisson Drilling

Understanding the Fundamentals of Caisson Drilling for Engineers is crucial in the construction of foundations at significant depths. Caissons, also known as drilled shafts, play a vital role in providing deep foundation support for structures. Engineers must determine the size and depth of the caisson needed to support the structure based on various factors such as loads, bedrock availability, and soil conditions. Drilling caissons involves creating a cylindrical hole in the ground and filling it with fresh concrete, forming a solid foundation that can bear the weight of the structure. This method allows for flexibility in design, as a single drilled shaft may be used instead of a group of piles, along with a pile cap, to support the structure effectively. The understanding of caisson drilling is essential for engineers involved in various construction projects.

Caisson drilling, also known as foundation drilling, is a construction method that involves excavating and creating a hollow cylindrical structure known as a caisson. Understanding the basics of caisson drilling is crucial for engineers as it forms the foundation for many structures. Caissons are most commonly used in areas where traditional shallow foundations are not feasible due to soil conditions, loads, or the need for deep foundation support. The construction of a caisson involves drilling a hole into the ground and filling it with fresh concrete, creating a solid column that provides stability and support to the structure above. Caisson drilling is a complex process that requires specialized equipment such as drill rigs, rotators, vibro hammers, and oscillators. Through this method, engineers can ensure the safe and efficient construction of foundations in various construction projects.

Historical Background of this Innovative Method

Understanding the fundamentals of caisson drilling for engineers requires knowledge of the historical background of this innovative method. Caisson construction has been used for centuries in the building of foundations at significant depths. The caisson construction process involves drilling cylindrical holes into the ground, creating compartments that are then filled with fresh concrete. This deep foundation support method is crucial in projects where traditional shallow foundations cannot provide the necessary stability. Understanding the history of caissons and their role in construction allows engineers to determine the size, depth, and type of caisson needed to support various structures.

Caisson drilling is a construction technique that dates back centuries and has been used in the construction of various structures, from bridges to harbor walls. The process involves drilling cylindrical holes into the ground, typically through layers of soil and rock, to create a foundation for the structure. Engineers must consider factors such as soil conditions, accessibility, and the bearing stratum to determine the appropriate depth and capacity of the caisson. The use of caissons offers several advantages, including increased stability, access to deeper depths, and the ability to withstand challenging site conditions. Caisson drilling requires specialized equipment and skilled workers, but the benefits it brings to construction projects, such as improved foundation support and reduced construction costs, make it a widely utilized technique in the industry.

Deep Dive into Caisson Drilling Mechanics

Understanding the fundamentals of caisson drilling is crucial for engineers involved in foundation methods. When considering the costs and project requirements, several factors must be taken into account, including water table levels, soil composition, and environmental conditions. The choice of caisson drilling as a foundation solution depends on the site investigation findings, dimensions, and caisson fabrication. Quality control is a vital process that outlines the steps and activities necessary to ensure the correct installation of caissons. Monitoring the effectiveness of caisson drilling is essential for planning and execution. The stability and support structures that caissons provide to buildings and other structures are among the benefits that engineers must consider. Caisson drilling allows for deep foundation construction at significant depths, and engineers must determine the size and depth of the caisson needed to support the structure. By understanding the fundamentals of caisson drilling, engineers can ensure the successful construction of foundations.

The Science Behind Caisson Drilling

Understanding the fundamentals of caisson drilling is essential for engineers involved in construction projects, especially those focused on building foundations and bridge structures. The science behind caisson drilling revolves around the rest and durability of the structures it supports. Caisson construction techniques and the use of specialized tools enable engineers to create a solid base for construction by drilling deep into the ground. Understanding the nitty-gritty of caisson drilling, such as the types of caissons, their advantages, and the placement of reinforcement bars, allows engineers to provide stability and flexibility to the structures they build. This expertise in caissons is a crucial factor when considering the construction technique and materials to use, as it ensures the longevity and reliability of the foundations being constructed.

Essential Tools and Equipment for the Job

Understanding the fundamentals of caisson drilling is essential for engineers involved in the construction of foundations at significant depths. Caissons, also known as drilled shafts, are deep foundation supports that are constructed by placing fresh concrete and reinforcement bars into a drilled hole. When utilizing caissons, engineers must determine the size and depth of the caisson needed to support the structure. This drilling technique is favored in areas with challenging soil conditions, such as high groundwater levels, earthquakes, or frost heave. The use of caissons offers several advantages, including the ability to withstand heavy loads, flexibility in design options, and increased structural integrity.

The construction of caissons requires specialized tools and equipment. Drill rigs, commonly powered by a diesel engine, are used to create the caisson hole. These drill rigs vary in size, weight, and drilling capacity, depending on the construction needs and site conditions. In addition to drill rigs, other essential tools for caisson drilling include core barrels, augers, and casings. Core barrels and augers are used to remove soil or other materials from the drill hole, while casings provide temporary support and prevent collapse during the drilling process. The selection of materials for casings is crucial to ensure their durability and corrosion resistance. Some popular choices include steel, wood, fiberglass, or PVC. The safe and efficient installation of caissons requires skilled contractors, architects, and designers who understand the specifications, space constraints, and safety regulations involved. By using these tools and equipment effectively, caisson drilling can be carried out with minimal disruption to the surrounding area and with the utmost attention to safety.

The Role of Caisson Drilling in the Field of Engineering

Understanding the Fundamentals of Caisson Drilling for Engineers is crucial in the construction industry, especially when it comes to the role of caisson drilling in the field of engineering. Caisson drilling is a foundation system that is used to support structures in areas with challenging terrain or soil conditions. It involves the installation of large cylindrical structures called caissons into the ground to provide stability and integrity to the foundation. These caissons can be in the form of open-ended or closed-ended boxes, depending on the specific requirements of the project. Caisson construction presents several advantages, such as the ability to bear heavy loads, retain soil in retaining structures, and withstand harsh environmental conditions. With advancements in design features and innovations in construction techniques, caisson drilling has become a cornerstone in the construction of skyscrapers and other large-scale buildings. The use of caissons can also be seen in bridge construction, where they provide stability and support to bridge piers. In addition to their structural role, caissons have also been utilized in various other applications, such as the sinking process of well foundations and the construction of cofferdams. Their versatility and performance in different construction scenarios highlight the importance of understanding the basics of caisson drilling for engineers. By incorporating caissons into their projects, engineers can ensure the efficiency, safety, and stability of their construction projects.

Structural Engineering and Its Reliance on Caisson Drilling

Understanding the Fundamentals of Caisson Drilling for Engineers is crucial when it comes to the construction of foundations at significant depths. Structural engineering often relies on caissons, which are cylindrical structures that are used to support various types of structures, such as bridge piers and buildings. Engineers need to carefully evaluate the circumstances, weight, and materials of the structure to determine the size and depth of the caisson needed to support the structure. Caisson construction involves the excavation of the ground to create a cavity, which is then filled with concrete to form a strong foundation option. Despite its many benefits, such as the ability to penetrate surface layers and act as a watertight concrete box (as seen in the iconic Brooklyn Bridge), there are also downsides to caissons, such as the challenges associated with working in underwater environments and the potential for water intrusion during the installation process.

Caissons play a crucial role in providing support and resistance to various loads in construction sites. The caisson foundations are designed to withstand the pressures and loads imposed on them, making them a preferred choice for engineers in challenging soil conditions. The bearing capacity and load resistance of caissons are determined by their design features, including the placement, depth, and size of caissons, as well as the site conditions and pressure exerted by the surrounding environment. Caisson performance is influenced by a range of factors, including the soil conditions, loading capacity, and the construction site’s environment. With advancements in caisson technology, engineers can now achieve greater precision in the construction process and better adapt to different soil conditions and settings. In underwater excavation techniques, caissons are used to form a seal at the bottom to prevent water inflow during the construction process. Caissons contractors employ various methods to ensure the bottom seal is properly formed and resistant to water intrusion, enhancing the resilience and durability of the caisson foundation systems.

Enhancing the Engineering World Through Precision Drilling

Understanding the fundamentals of caisson drilling is crucial for engineers involved in the construction of foundations at significant depths. Caissons are foundation elements that must be carefully designed and installed to ensure the stability and longevity of structures. Engineers must determine the size and depth of the caisson needed to support the structure, taking into consideration factors such as soil properties, groundwater presence, and the load-bearing capacity required. Drilling caissons involves creating underwater air chambers, control systems, and defense against disasters and hazards. It also requires expertise in caisson materials and engineering, as well as adherence to construction standards. With the right skills, knowledge, and attention to detail, engineers can mitigate risks and enhance the effectiveness of caisson construction.

Furthermore, caisson drilling has seen significant developments and improvements over the years, thanks to advancements in technology and engineering practices. For example, the construction of the Burj Khalifa in Dubai, one of the world’s tallest towers, relied heavily on caissons for its foundation. The introduction of automation in caisson construction has not only improved efficiency but also ensured the accuracy of reinforcement placement and overall results. Construction professionals now have the ability to monitor the drilling process, collect data, analyze it, and make necessary adjustments to ensure the durability and reliability of caisson foundations. With the use of technology and adherence to safety measures, caisson drilling has become a staple in the creation of load-bearing structures, such as suspension bridges and storage schemes for dams. The advancements in caisson technology have pushed the boundaries of what is achievable in engineering, making it an essential component in modern construction practices.

Weighing the Pros and Cons of Caisson Drilling

Understanding the Pros and Cons of Caisson Drilling is essential for engineers involved in the construction of foundations at significant depths. Caissons, also known as drilled shaft foundations, are an important element in stabilizing structures such as bridges, buildings, and transportation structures. Engineers must determine the size and depth of the caisson needed to support the structure and ensure its stability. While caisson drilling offers advantages such as the ability to construct deep foundation support by placing fresh concrete and the potential to use a single drilled shaft instead of a group of piles and the pile cap, it also has its drawbacks. These include the complexity of construction methods, the need for specialized equipment, and the challenges in accurately placing and selecting concrete for the caissons. Despite these considerations, caisson drilling remains a valuable technique in foundation construction, especially in areas with challenging soil conditions or where other foundation choices may not be suitable.

Benefits of Harnessing Caisson Drilling Techniques

Understanding the fundamentals of caisson drilling is crucial for engineers involved in the construction of foundations at significant depths. Caissons, also known as drilled shafts, are deep foundation support structures that are constructed by placing fresh concrete and reinforcing steel into a drilled hole. Before proceeding with caisson drilling, engineers must determine the size and depth of the caisson needed to support the structure. The use of caissons allows for a single drilled shaft to be used instead of a group of piles and the pile cap, reducing costs and simplifying the construction process.

Caisson drilling offers several benefits for engineers. First, it provides a more reliable foundation compared to other methods. By drilling deep into the ground, caissons are able to reach bedrock or a stable soil layer, ensuring a strong foundation for the structure. Additionally, caissons can be designed to withstand specific loadings and soil conditions, offering a high level of flexibility in design. This allows engineers to tailor the caisson design approach to meet the specific demands of each project. Overall, caisson drilling provides engineers with a reliable and efficient method for constructing deep foundations, ensuring the stability and longevity of the structure.

Addressing Challenges and Drawbacks in Caisson Drilling

Understanding the Fundamentals of Caisson Drilling for Engineers is crucial for addressing challenges and drawbacks in this construction method. The principles of caisson drilling are based on the performance of the material properties, as well as the determination of the formation and size of the caissons. Engineers must ensure that the city’s project requirements are met, including cost estimation, inspection, and adherence to safety issues. Additionally, the depth and bearing stratum of the soil must be considered to ensure the stability of the caisson and the overall foundation. By understanding these details and employing proper techniques, engineers can mitigate potential deviations and ensure the success of caisson drilling projects.

Caisson drilling in the construction of foundations at significant depths presents both advantages and challenges for engineers. Caissons, which are large-diameter columns drilled into the ground, offer a viable deep foundation support option. However, understanding the fundamentals of caisson drilling is essential for engineers to determine the size and depth of the caisson needed to support the structure effectively. The construction process involves drilling caissons into the ground, either by using an auger or a bucket-type auger machine. Engineers must carefully consider ground conditions, such as groundwater and soil type, to ensure the stability and integrity of the caisson. By addressing these challenges and mastering the required techniques, engineers can successfully utilize caisson drilling for the construction of sturdy and reliable foundations.

Realworld Implementations of Caisson Drilling

Understanding the Fundamentals of Caisson Drilling for Engineers is crucial when it comes to the construction of foundations at significant depths. Caissons, also known as drilled shafts or drilled piers, are deep foundation supports that are constructed by placing fresh concrete and reinforcing steel into drilled holes. Engineers must determine the size and depth of the caisson needed to support the structure based on factors such as the load-bearing capacity of the soil or rock profiles. Caisson drilling offers several advantages over other foundation alternatives, such as increased strength and reliability in supporting heavy foundation loads. This makes it the ideal choice in areas where cofferdam construction is not feasible or where settlement is a concern. Real-world implementations of caisson drilling can be seen in cities like New York, where the use of caissons has become common practice in city building projects. Well-known structures such as the Brooklyn Bridge and the Freedom Tower have relied on caissons for their foundations. The adoption of caisson drilling techniques by architects and engineers has revolutionized the construction industry, providing a reliable and efficient solution for supporting structures in challenging soil conditions.

Understanding the Practical Applications of Caisson Drilling

Understanding the fundamentals of caisson drilling is crucial for engineers involved in the construction of foundations at significant depths. Caissons, also known as drilled shafts, are a deep foundation support system constructed by placing fresh concrete and reinforcement into a drilled hole. The size and depth of the caisson must be carefully determined to provide the necessary support for the structure. Unlike traditional pile foundations, a single drilled shaft can be used instead of a group of piles, reducing construction complexity and the need for a pile cap.

Drilling caissons involves using specialized equipment and techniques. One common method is the bucket-auger machine, which utilizes a rotating bucket that cuts into the ground and removes the soil. Another technique is underreaming, where the diameter of the caisson is expanded at the bottom to increase its bearing capacity. Pioneers in the caisson drilling industry, such as the Beck Company and Greer Construction Co., played a vital role in developing innovative machines and techniques during World War II and the subsequent building boom. Today, caisson drilling continues to be used in a wide range of applications, from building bridges and retaining structures to constructing dams and repairing ships.

Conclusion

Understanding the Fundamentals of Caisson Drilling for Engineers is crucial when it comes to the construction of foundations at significant depths. Caissons, also known as drilled shafts or drilled piers, provide deep foundation support that is constructed by placing fresh concrete and reinforcement in a drilled hole. Engineers must determine the size and depth of the caisson needed to support the structure, taking into consideration factors such as the load capacity, soil conditions, and design requirements. By drilling caissons instead of using traditional shallow foundations or piles, engineers can achieve greater stability and resistance to problems such as building settlement, vibrations, and water infiltration. The construction expertise required for caisson foundations is specialized due to the complex drilling procedures and the need to ensure the integrity of the structure. However, there are both advantages and disadvantages to caisson drilling, and engineers must carefully evaluate the site conditions, project requirements, and economics before deciding to utilize this deep foundation method.

FAQS

What is caisson drilling?

Caisson drilling is a method used in engineering to create deep foundation structures. It involves drilling cylindrical shafts into the ground and filling them with concrete or other structural materials.

How does caisson drilling work?

Caisson drilling works by using large drilling rigs to bore deep into the ground. The drilling rig creates a hole in the soil or bedrock, and then a reinforcing cage is placed in the hole. Finally, concrete is poured into the hole to create a strong foundation.

What is the historical background of caisson drilling?

Caisson drilling has been used for centuries, dating back to ancient civilizations. It was first used in bridge construction during the 19th century and has since become a common method in various engineering fields.

What are the essential tools and equipment used in caisson drilling?

The tools and equipment used in caisson drilling include large drilling rigs, drill bits, reinforcing cages, and concrete pumps. These tools are necessary for creating stable and durable foundation structures.

What is the role of caisson drilling in the field of engineering?

Caisson drilling plays a crucial role in engineering as it allows for the construction of deep foundation structures. It is commonly used in bridge construction, high-rise buildings, and other projects that require strong and stable foundations.

What are the benefits of harnessing caisson drilling techniques?

Some benefits of using caisson drilling techniques include increased stability and load-bearing capacity of structures, reduced settlement, and the ability to build in challenging soil or water conditions.

What are the challenges and drawbacks of caisson drilling?

Challenges and drawbacks of caisson drilling include the high cost of equipment and labor, the potential for encountering underground obstacles, and the need for careful planning and engineering expertise.

How can caisson drilling enhance the engineering world through precision drilling?

Caisson drilling allows engineers to create precise and controlled foundation structures. This precision drilling ensures that structures are built with the required strength and stability, reducing the risk of failure or collapse.

What are some real-world implementations of caisson drilling?

Caisson drilling has been used in various real-world projects, including the construction of bridges, high-rise buildings, offshore structures, and even deep-water oil rigs. These applications demonstrate the versatility and effectiveness of caisson drilling.

What are the practical applications of caisson drilling?

Practical applications of caisson drilling include creating foundations for buildings, bridges, piers, and other structures that require deep and stable foundations. It is also used in geotechnical investigations and soil sampling.

In conclusion, what are the key takeaways about caisson drilling for engineers?

Caisson drilling is a vital method in engineering that allows for the creation of deep and stable foundation structures. It has a rich historical background and relies on precise drilling techniques and specialized equipment. While it has its challenges and drawbacks, caisson drilling offers numerous benefits and has been successfully implemented in various real-world projects.